Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

In manufacturing production, the quality inspection of castings is a crucial link. Due to the structural complexity of castings and strict requirements for product quality, the detection of internal defects is particularly important.

Table of contents

1.Introduction

2.How to ensure that the quality of castings meets requirements

3.Advantages of VS-F series desktop industrial endoscopes

4.Customized detection solutions for different types of pipelines

5.Application scenarios

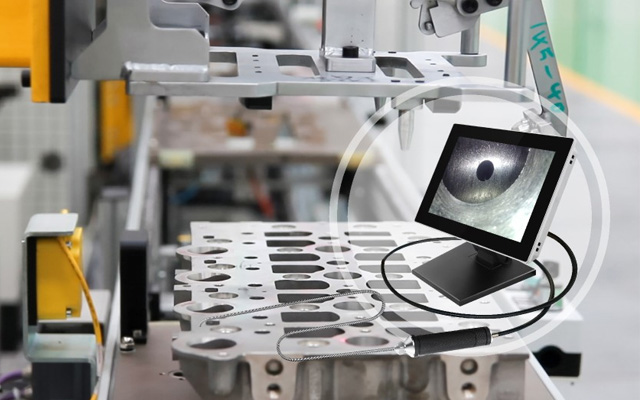

As an advanced inspection tool, the VS-F series desktop industrial endoscope provides a new solution for precision machining and the detection of internal defects in castings.

Desktop industrial endoscopes can detect the classification of castings in different industries, including: automotive parts castings, hydraulic parts castings, pump body and valve body castings, mechanical parts castings, pipeline fittings castings and pneumatic parts Unit castings.

The VS-F series desktop industrial endoscope is a high-definition video endoscope specially built for industrial-grade inspection, featuring high definition, high resolution and high frame rate. Users can easily observe and detect subtle defects inside precision castings, such as pores, cracks, inclusions, etc. At the same time, the endoscope is also equipped with a high-precision image processing system and measurement functions, which can achieve precise dimensional measurement and defect location to ensure that the quality of castings meets requirements.

VS-F series desktop 15.6-inch screenSpring tube detection effect

Main features: The spring elbow probe is suitable for testing the flow path of the turbine shell of rough parts. The rear spring tube is made of stainless steel, and the front hardware elbow is made of alloy. Wear-resistant, anti-corrosion, good toughness, not easily deformed, long service life.

Main features: Alloy rigid probe is suitable for straight hole inspection of pump valves, pump bodies and hydraulic parts, and is made of alloy material. It is wear-resistant, anti-corrosion, has good toughness and is not easily deformed, and has a long service life.

Main features: handheld all-in-one machine, desktop separator, suitable for precision castings with complex internal structures, various types of engines, cylinder blocks and heads, aircraft engines, wind turbine blades, gearboxes, etc., 360° all-round guidance, arbitrary observation Every part. It adopts tungsten wire wear-resistant tube, flexible polyurethane inner layer + EODM to resist corrosion, oil, water and corrosion.

Main features: alloy hard rod side-view mirror machined precision parts, hydraulic parts cross hole closure, burrs, cracks and other surface details are detected, using alloy rod material. It is wear-resistant, anti-corrosion, has good toughness and is not easily deformed, and has a long service life.

In the precision casting inspection solution, the VS-F series desktop industrial borescope has a wide range of application scenarios. For example, in the fields of automobile manufacturing, aerospace, petrochemical industry, energy and other fields, this equipment can be used to detect internal defects of various precision castings.

In short, the VS-F series desktop industrial endoscope, as a non-destructive testing tool independently developed by VSNDT, provides an efficient and accurate solution for the detection of internal defects in precision machining and castings. Through the detection assistance of this equipment, manufacturing companies can better control the quality of castings and improve product reliability and safety. This is of great significance for ensuring product quality and improving production efficiency.

Industrial borescope

solution service provider