Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

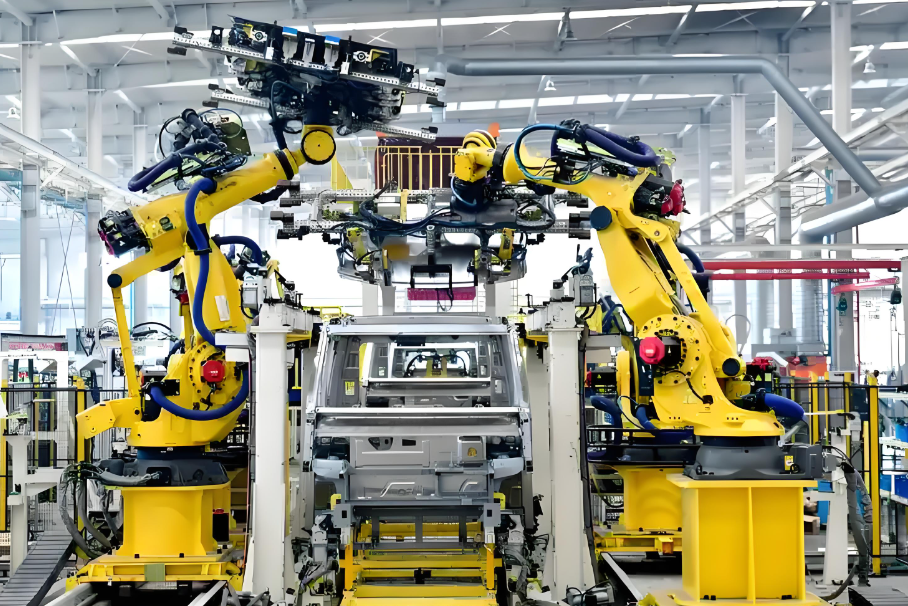

As a core tool for modern industrial inspection, industrial endoscopes play an irreplaceable role in the field of mechanical manufacturing. Through non-destructive testing, high-precision imaging and real-time data analysis, they have achieved a comprehensive upgrade from quality control to equipment maintenance. The following is a detailed analysis of specific application scenarios and technical advantages:

Quality inspection of precision parts

Application case: In the manufacturing of automobile engine blocks and turbochargers, industrial endoscopes can detect microscopic defects such as pores and inclusions inside aluminum alloy castings to avoid engine failures caused by internal quality problems.

Application case: In wind turbine gearbox inspection, endoscopes can detect gear wear in advance through flexible probes (such as the Microvision Optoelectronics P series, which can be extended to 10 meters), avoid gear breakage accidents, and significantly reduce the risk of unplanned downtime.

Technical advantages: Flexible tungsten wire braided tube or snake bone joint technology can achieve 360° bending, adapting to complex cavity detection, while supporting real-time image transmission to facilitate remote expert diagnosis.

Application case: In the aerospace field, endoscopes are used to check the welding quality of rocket engine combustion chambers and turbine blades to ensure that the welds are free of defects such as cracks and pores, thereby ensuring flight safety.

Innovative function: 3D measurement technology ( Microvision Optoelectronics ) can accurately measure the height and width of welds, and guide the grinding process to improve assembly accuracy.

Predictive maintenance and failure prevention

Application case: In nuclear power plant pipeline inspection, endoscopes can detect early cracks in welds and avoid the risk of radioactive leakage. By integrating with the MES system, real-time upload of inspection data is achieved, and an equipment health management platform is built.

Technology trends: Combined with AI algorithms, it can automatically identify defects and predict the remaining life of equipment, driving the maintenance model from "passive maintenance" to "active prevention."

High definition and miniaturization: Imaging technology is upgraded to 8K, and the probe diameter continues to shrink to adapt to detection in smaller spaces.

Multifunctional integration: Integrates temperature, pressure, chemical analysis and other functions to provide a one-stop detection solution.

Green and environmentally friendly: Made of environmentally friendly materials, it reduces energy consumption and waste emissions, meeting the needs of sustainable development.

Industrial endoscopes have become the "perspective eyes" for quality control and equipment maintenance in the field of mechanical manufacturing. Through technological innovation and intelligent upgrades, they have not only improved production efficiency and safety, but also promoted the transformation of industrial inspection to predictive maintenance and green manufacturing. As the global manufacturing industry accelerates its intelligentization process, the market penetration rate of industrial endoscopes will continue to rise. It is estimated that the global market size will reach 6.03 billion yuan in 2030, with a compound annual growth rate of 5.4%.

Industrial borescope

solution service provider