Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

Every reform and innovation in the automotive industry may have a profound impact on our way of traveling. In every link of the automobile manufacturing process, precision and reliability are undoubtedly the top priority.

Do you know that behind the automobile manufacturing, there is a mysterious tool that is quietly playing a vital role? This is the industrial borescope.

Industrial borescopes, as the name implies, are tools that can "peek" into industrial equipment. They are used in a wide range of applications, but they are an irreplaceable key device in the inspection and maintenance of precision automotive parts.

When we talk about precision automotive parts, we first think of core components such as engines, gearboxes, and turbochargers. Once problems occur in these components, they often bring fatal blows to the vehicle.

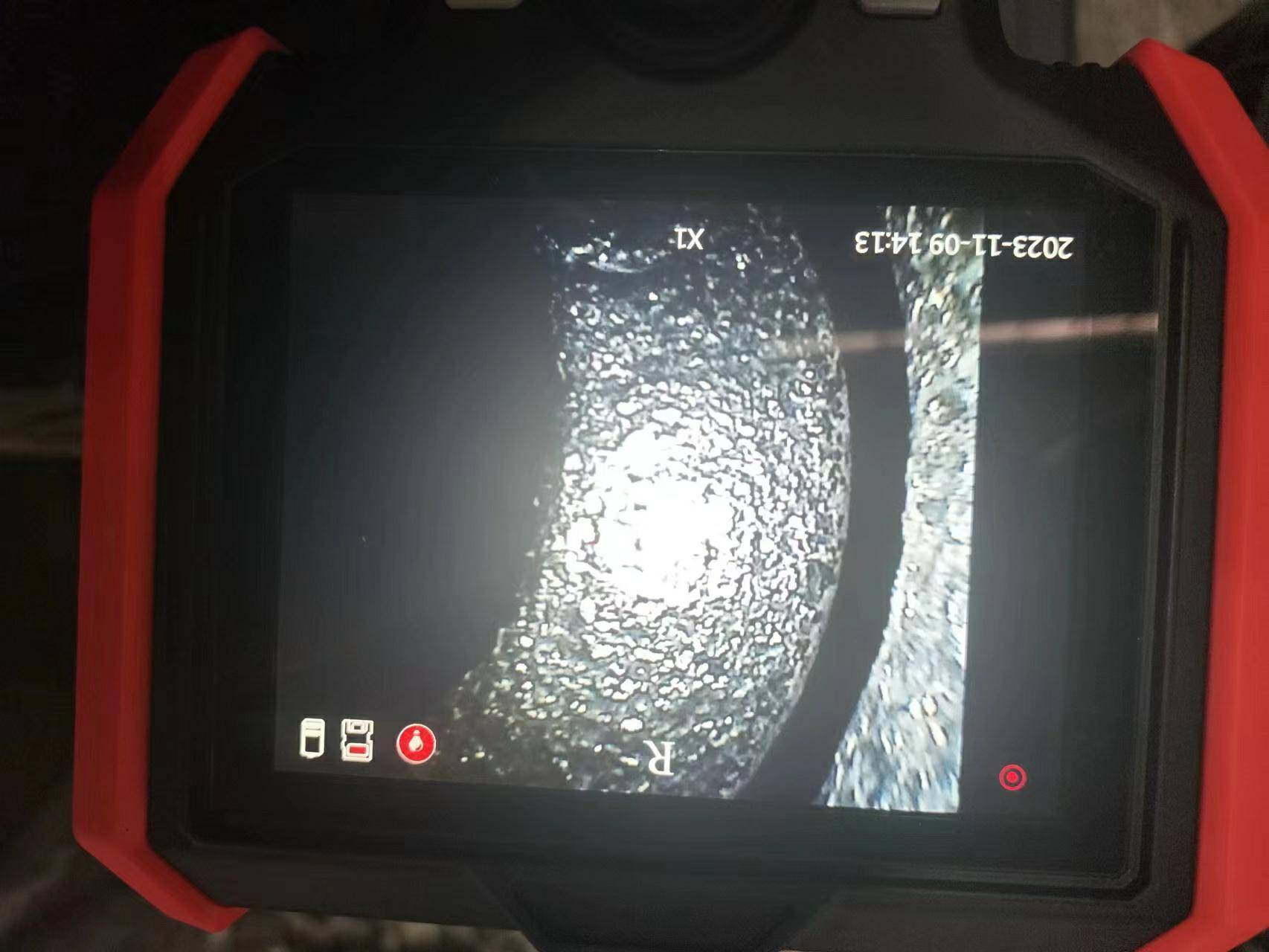

As a high-tech inspection tool, industrial borescopes can conduct in-depth inspections inside cars through their flexible probes and high-definition imaging systems without disassembling the equipment. For example, in engine inspections, endoscopes can enter cylinders, pistons, valves and other parts to accurately detect wear, carbon deposits, cracks and other problems, thereby avoiding many potential fault hazards. Similarly, in the inspection of gearboxes, endoscopes can easily enter the complex gear sets to check the operating status of each gear and ensure the smooth operation of the gearbox.

VSNDT focuses on the design, technology development, production, sales and technical services of high-pixel industrial endoscope products. Its products are also widely used in precision automobile manufacturing inspection.

Recently, VSNDT according to the specific needs from a precision automotive parts manufacturer. We in-depth research on customer needs and, Based on independently developed industrial endoscope technology, customized a set of efficient and accurate industrial borescope for customers. The K series video borescope can conduct all-round and no-dead-angle inspections on the complex structures and tiny defects of automotive parts to ensure that the quality and performance of parts meet the design requirements.

High-definition, portable, and highly flexible

VSNDT’S industrial borescope products (K series) are high-definition, portable, and highly flexible, integrating high-resolution image sensors, ultra-bright LED light sources, and intelligent image processing algorithms.

Fast and accurate detection

These advanced technical features enable the borescope to easily penetrate narrow spaces and achieve accurate inspection of the internal structure of automotive parts.

At the same time, the borescope can also clearly display subtle defects such as cracks, corrosion, and foreign body blockage inside parts, helping inspectors to promptly discover and deal with potential problems.

More cost-effective

Compared with traditional inspection methods, VSNDT' industrial borescope equipment significantly shortens the inspection cycle and reduces manual intervention and disassembly costs.

Efficient detection

With the assistance of high-definition images and intelligent algorithms, inspectors can complete inspection tasks more quickly and accurately, improving the accuracy and consistency of inspections. This not only reduces the company's operating costs, but also improves the overall quality and market competitiveness of the product.

The production quality of automotive parts has been improved by adopting advanced detection technology solutions. During the production process, manufacturers can use endoscopes to conduct strict quality control on each component to ensure that it meets the design standards. Any minor defects can be discovered and corrected in time on the production line, thereby improving the overall quality of the product. This well-known precision automotive parts manufacturer has further consolidated its leading position in the industry.

VSNDT' industrial borescope solution not only improves the inspection level of parts, but also provides consumers with safer and more reliable automotive products. This helps to enhance the brand's market competitiveness and user trust, and lay a solid foundation for the sustainable development of the company.

VSNDT ‘ industrial borescopes have played an important role in parts inspection for a well-known precision auto parts manufacturer. By providing customized solutions, high-performance products and efficient inspection services, VSNDT not only improves the company's inspection level and product quality, but also brings significant economic and social benefits to the company. This successful case not only reflects the technical strength and innovative spirit of VSNDT company, but also provides a inspection solution that can be used as a reference for more industries.

Industrial borescope

solution service provider