Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

As an advanced inspection tool, VSNDT industrial endoscope plays an increasingly important role in the field of rail transit inspection.

Track surface inspection: Industrial endoscopes can perform non-destructive inspection of the track surface through the front-end lens of the pipeline, including cracks, potholes, rust and other issues on the track surface. This helps to promptly detect and resolve defects on the track surface and ensure the safe operation of trains.

Internal equipment inspection: Industrial endoscopes can be inserted into the equipment to inspect the internal components and structures of the equipment. For example, key components such as bogies and traction motors of subway vehicles are tested to determine whether they are operating normally and whether there are any safety hazards.

Axle defect detection: As an important component in railway transportation, train axles are very important in terms of manufacturing technology and quality detection methods. The detection parts mainly include the shaft end, axle body and axle box. It is necessary to focus on detecting whether there are fatigue cracks, corrosion and mechanical defects. sexual injury.

Construction process monitoring: During the construction process of rail transit, industrial endoscopes can be used to monitor the quality and safety of the construction process. For example, during the excavation process of a subway tunnel, the condition of the excavation surface can be observed in real time through an endoscope, and possible safety hazards can be discovered and dealt with in a timely manner.

High-definition imaging: VSNDT industrial endoscopes use advanced image sensors and digital processing technology to provide clear and detailed images, providing inspection personnel with accurate visual information.

Strong flexibility: VSNDT industrial endoscopes can be customized with 0.95-8mm pipeline diameter and ≥180° probe bending angle, and can adapt to various complex inspection environments. At the same time, its lightweight and portable design also allows inspection personnel to easily operate it on site.

High reliability: VSNDT industrial endoscopes are waterproof, dustproof, and high temperature resistant, and can operate stably in harsh environmental conditions. In addition, its long-life design also reduces the frequency of maintenance and replacement, reducing operating costs.

Intelligent operation: VSNDT industrial endoscope is equipped with an intelligent operating system, and inspectors can perform intuitive operations through the touch screen or buttons. At the same time, its automatic detection function can also automatically identify and alarm defects, improving the accuracy and efficiency of detection.

Cooperative enterprise: Shenzhen Metro

Detection object: The condition of the air cylinder welding joint and the compressed air pipe

Purpose of inspection: Check whether there are cracks in the air cylinder and whether there are cracks or trachoma in the compressed air pipe.

Difficulties in detection: The detection point is located in a small space between the carriage and the base, making it difficult to fully detect it with the naked eye.

Solution: VSNDT VS-K series video endoscope and auxiliary rod can play a role in straightening and fixing the pipeline, allowing its probe to penetrate deep into the detection site, clearly showing the complete status of the trachea in front of our eyes, allowing We can easily observe the presence of cracks and trachoma in the trachea.

Cooperating enterprise: CRRC

Detection object: Inside the locomotive track bracket

Inspection purpose: Check whether the internal welding is complete, whether there is any excess material, whether the spray paint is uniform, etc. Visual environment inspection

Difficulties in detection: The internal space of the locomotive track bracket is large, and the length and pixel requirements of the pipeline are relatively high.

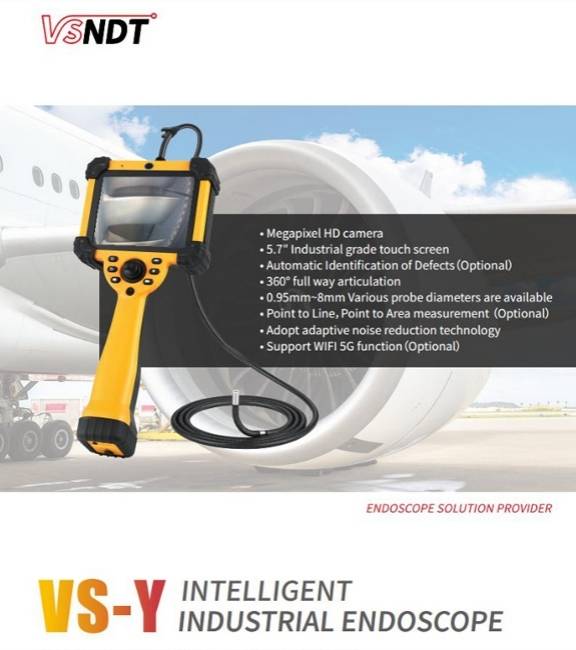

Solution: VSNDT VS-Y series smart industrial endoscope, customized with 5-meter-long pipeline with megapixels and rear fiber optic endoscope probe, which can quickly detect and operate flexibly, and quickly mark the endoscope inspection video of the number of track brackets or Pictures can be watermarked to facilitate later reporting and comparison and tracing of drawings and objects, providing convenient support.

This case is a cooperative inspection case between VSNDT and BYD Sky Rail Project. The purpose of the inspection requires that internal defects and problems in various parts of the track can be clearly observed, such as welding defects, material cracks, rust, etc. Through the detection and analysis of these problems, potential safety hazards can be discovered in time, and corresponding measures can be taken for repair and replacement.

In the inspection of BYD Cloud Track, the application of industrial endoscopes realizes non-destructive inspection and avoids the limitations of traditional inspection methods. At the same time, its advantages such as high-definition imaging, strong flexibility, high reliability, and intelligent operation make the detection process more accurate and efficient.

Industrial borescope

solution service provider