Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

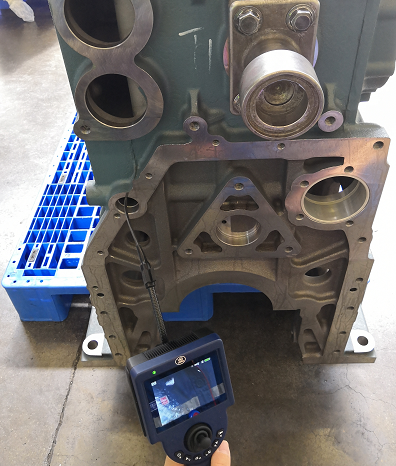

In recent years, with the continuous advancement of shipbuilding technology, the complexity and precision of ship engines have increased, and higher requirements have been placed on engine detection and maintenance. A well-known shipbuilding company, as a leading enterprise in the domestic shipbuilding industry, actively introduced advanced detection equipment to improve the efficiency and accuracy of engine detection. Among them, the Shenzhen VSNDT Y series industrial endoscope has become an important tool for the company's engine detection.

High-definition imaging and intelligent operation

High-definition camera: The Y series industrial endoscope is equipped with a million-level high-definition camera, which can capture clear and delicate images, allowing inspectors to accurately observe the subtle conditions inside the engine, such as the operating status of key components such as pistons, cylinders, valves, crankshafts, etc.

Intelligent operating system: The device has a built-in intelligent operating system, which is easy to operate and supports real-time network connection. It can be equipped with Wi-Fi and 5G functions to achieve fast data transmission and remote collaboration.

Flexible probe and all-round observation

Flexible probe: The probe is flexible in design, can be bent and retracted, and can be customized in the diameter range of 0.8-8mm. It can easily enter various complex spaces inside the engine to meet different inspection needs.

360° all-round observation: The probe has a 360° all-round rotation function, and the minimum guide angle can reach 160°, ensuring that there is no dead angle in the inspection and fully grasping the internal conditions of the engine.

Powerful functions and efficient detection

Multiple measurement functions: Supports point-to-point, point-to-line, and area measurement, providing inspectors with accurate dimensional data, which helps to discover potential wear or deformation problems.

Adaptive noise reduction technology: Using advanced adaptive noise reduction technology to capture highly clear static pictures, image quality can be guaranteed even in low-light environments.

Real-time video and image recording: Supports real-time video and image recording and storage, which facilitates subsequent analysis and diagnosis and improves detection efficiency.

Durable design and safety protection

Durable materials: The probe and pipeline are made of wear-resistant, oil-resistant and corrosion-resistant materials to adapt to various harsh detection environments.

High protection level: host IP55, probe IP68, waterproof, dustproof and corrosion-resistant, ensuring stable operation of the equipment in complex environments.

Real-time monitoring and fault prevention

Ship engines have complex structures and high sealing. Traditional detection methods often require disassembly of the engine, which is time-consuming, labor-intensive and costly. The Y series industrial endoscope can enter the engine through hatches or other entrances, monitor the operation of key components in real time, and promptly detect abnormal conditions such as wear, cracks, and carbon deposition to prevent faults.

Improve detection efficiency and accuracy

Inspectors can conduct comprehensive inspections without disassembling the engine, which greatly shortens the inspection time and improves the inspection efficiency. At the same time, high-definition imaging and intelligent operating systems ensure the accuracy of the inspection and provide strong guarantees for the safe navigation of the ship.

Reduce maintenance costs and downtime

By regularly using the Y series industrial endoscope to inspect the ship engine, potential problems can be discovered and dealt with in a timely manner to avoid greater losses caused by the expansion of faults. This helps to reduce maintenance costs, reduce downtime, and improve the efficiency and economic benefits of ship transportation.

The Shenzhen VSNDT Y series industrial endoscope has played an important role in ship engine inspection with its advantages of high-definition imaging, intelligent operation, flexible probes and all-round observation. It not only improves the inspection efficiency and accuracy, but also reduces maintenance costs and downtime, bringing significant economic benefits to shipbuilding companies. In the future, with the continuous advancement of technology and the continuous expansion of application scenarios, the Y series industrial endoscope will play a more extensive and in-depth role in the field of shipbuilding.

Industrial borescope

solution service provider