Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

Industrial endoscope imaging technology covers two major systems: optical principles and electronic imaging, and integrates intelligent functions to improve detection capabilities. The following is a detailed introduction:

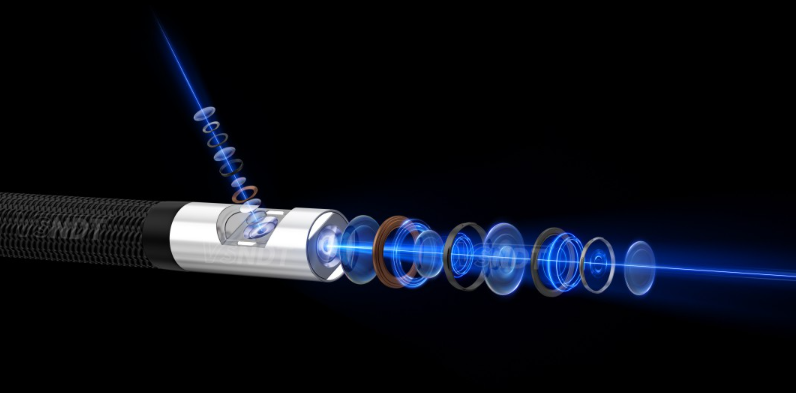

Optical imaging principle:Traditional industrial endoscopes use optical principles. A flexible or rigid probe is inserted into the area to be inspected. After the light source illuminates the target, the reflected light is transmitted to the other end of the probe through the lens, and then the image is transmitted to the display screen through the visual device. This method relies on an optical lens group to achieve imaging and is suitable for scenes with high real-time requirements and less environmental interference.

Electronic imaging principle: Modern industrial endoscopes mostly use camera technology, using a micro camera to capture the image of the target area and transmit it to an external display screen in real time through a video cable. This technology is based on electronic sensors (such as CCD or CMOS) to convert light signals into electrical signals, and then output visual images after processing, with higher flexibility and data recording capabilities.

Industrial fiber endoscope: The image transmission from the probe to the eyepiece is realized through the imaging fiber bundle. Each fiber transmits a single light spot, and finally presents a complete picture at the eyepiece end. It has a compact structure, is soft and bendable, and is suitable for inspection tasks in narrow or curved channels, such as turbine blades and internal inspection of small-diameter pipes.

Optical straight-rod endoscope: After the high-precision lens at the front end captures the image, it is transmitted to the eyepiece through the optical lens group, with high imaging fidelity. Since the mirror body adopts a metal tubular design and cannot be bent, it is mainly used for straight channel inspection, such as metal die-castings, machined parts and bolt hole internal observation.

Industrial video endoscope: The camera at the front end of the probe converts the endoscopic image into an electronic signal, which is transmitted to the handheld screen via a video cable. This technology uses digital imaging and integrated design, supports real-time recording and storage of static/dynamic images, and has more advanced quantitative measurement functions, which is suitable for internal inspection of complex equipment such as turbine engines and automobile engines.

High resolution and high sensitivity: Modern industrial endoscopes are generally equipped with high-pixel cameras, which can achieve 1080P or even higher resolution image output, and can clearly present tiny defects and complex structural details. At the same time, the high sensitivity design of the sensor ensures that high-quality images can still be obtained in low-light environments.

3D Stereo Measurement Technology: Using innovative measurement modes such as single objective lens phase scanning, quantitative analysis of defects can be achieved through 3D point cloud images. This technology can correct manual point selection deviations and connect with 3D printing technology to provide support for reverse engineering and quality inspection of complex parts.

Intelligent image processing: Integrates machine learning and neural network algorithms to automatically identify typical defect types such as cracks and corrosion and generate inspection reports. This function significantly improves inspection efficiency and reduces human errors, and is particularly suitable for quality control of large-scale production lines.

Industrial borescope

solution service provider