Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

Although it isintuitive to disassemble and observe the auto parts, the process is verytime-consuming and labor-intensive, and the cost of maintenance and inspectionis quite high, and frequent disassembly will also affect the performance ofparts and shorten the service life;

The industrialvideoscopes can solve the problem of maintenance and disassembly and the cost,such as checking the problem of the car engine, without disassembly, the probeof the industrial videoscope can directly observe various problems inside theengine through the fuel injector and sparks; so in automobile maintenance, theapplication of industrial videoscopes has been quite extensive, such as:engine, spark plug, fuel injector, water tank, fuel tank, gearbox, engine andother parts of wear, blockage, foreign matter and other problems; no need todisassemble, reduce cost, improve efficiency, and avoid secondary damage causedby multiple disassembly;

Specificdetections for different situations are manifested in the following key areas:

1. Carbondeposition on spark plugs and pistons

Spark plugs andpistons are prone to internal carbon deposits due to different performances. Inthe past, they had to be disassembled to judge during inspections. Theprofessionalism of personnel is relatively high. However, if an industrialvideoscope is used, we can judge internal faults directly through the imagetransmitted back by the industrial videoscope.

2. Inspection of parts and castings

The internal inspection of various parts of the car is very important,because the internal structure is complex and the defects are small and easy tobe ignored, and it is difficult for human eyes to observe the interior of thecasting, so the inspection of industrial videoscopes is very important;

Mainly checkwhether there are cracks, blockages, rust stains, burrs and trachoma in theinterior, and the interior of the casting is relatively small, and the diameterof the endoscopic probe is usually required to be less than 4mm;

3.The innerwall of the exhaust pipe

Automobileexhaust pipes mainly need to look at the welds on the inner wall. Generally,the defects are relatively small. Since the inside of the pipe is verydifficult to observe with the naked eye, the small welding problems on theexhaust pipe wall can be easily observed with an industrial videoscope;

Industrialvideoscopes not only guarantee the quality of parts in automobile productionand manufacturing, but also play an important role in later maintenance. Theyare indispensable inspection tools for automobile manufacturers and automobilemaintenance companies;

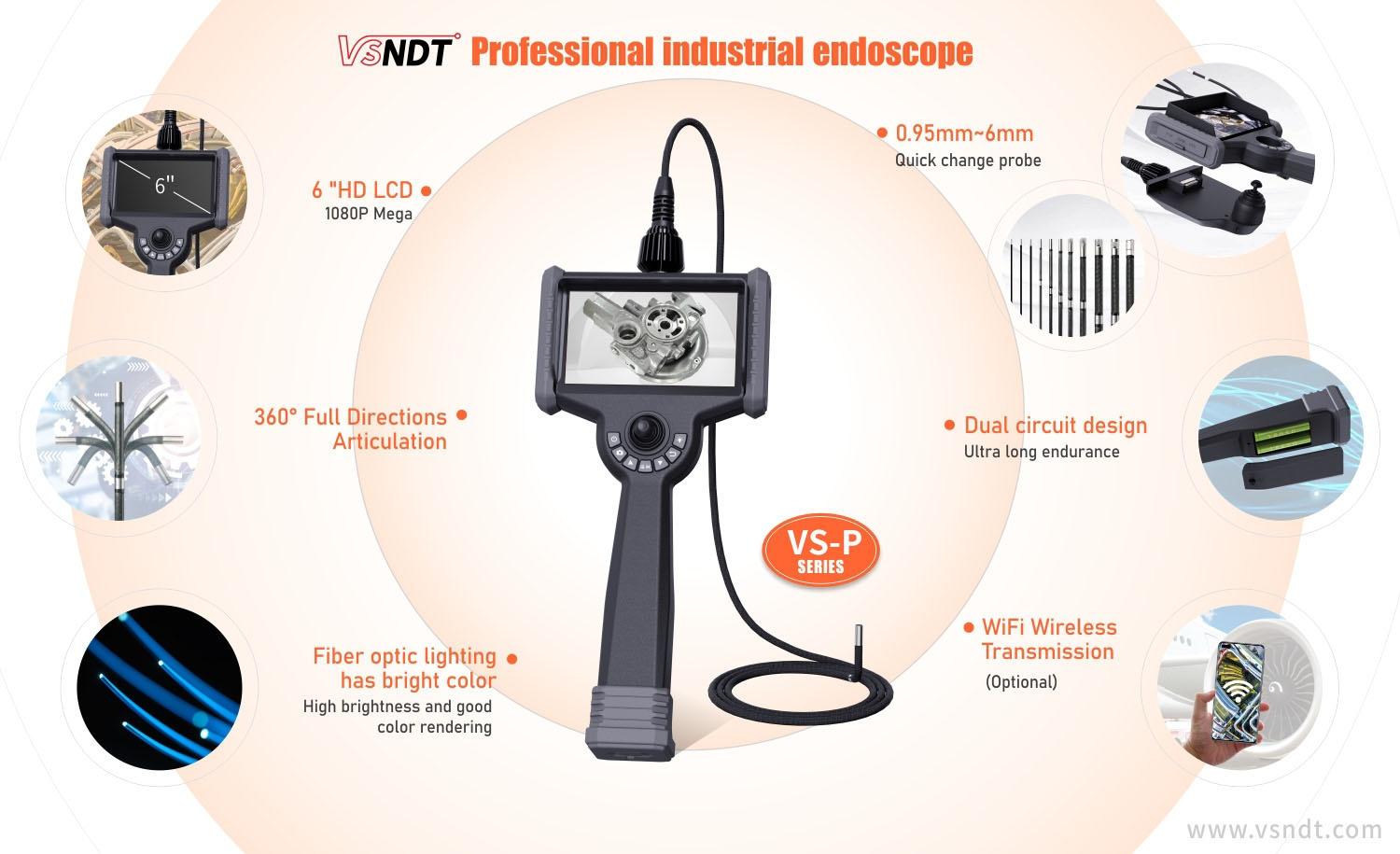

Shenzhen Vsndt Co.,Ltd specializes in R&D and production of various types of industrialendoscopes, which have been used in various fields of industry and have won thetrust of many customers. Welcome for cooperation!

Industrial borescope

solution service provider