Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

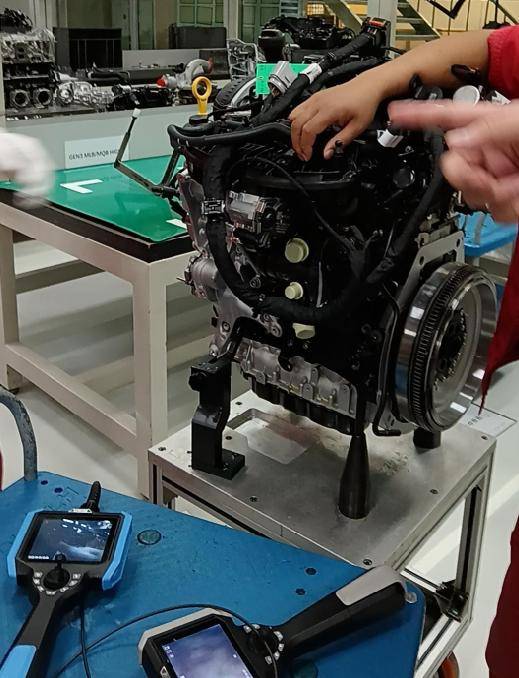

VSNDT K-Series Industrial Videoscopes, with their advanced technical specifications and features, demonstrate significant advantages in internal combustion engine inspections for automakers, as demonstrated in the following aspects:

Product Technical Specifications and Functional Advantages

High-Definition Imaging and Real-Time Transmission: K-Series videoscopes (such as the VS-K6010) are equipped with a 1-megapixel HD camera, capable of capturing subtle defects such as cracks and burrs within internal combustion engines. Images are transmitted to a monitor via Wi-Fi or HDMI in real time, enabling technicians to conduct immediate analysis.

Flexible Inspection and Environmental Resistance: The probe diameter ranges from 1.2 to 6mm, accommodating various internal combustion engine channel sizes. A 360° rotation function ensures comprehensive inspection without blind spots. Furthermore, with an IP67 waterproof rating and an operating temperature range of -20°C to 70°C, they operate reliably in harsh environments.

Data Storage and Portability: Built-in 32GB of storage supports long-term inspection data recording. The 5.7-inch LCD screen and portable design facilitate on-site operation.

Specific Applications in Internal Combustion Engine Inspection

Non-destructive Testing and Efficiency Improvement: Traditional internal combustion engine inspection requires disassembly of components, which is time-consuming and labor-intensive. The K-series endoscope can observe internal structures such as cylinders and turbines through small access points, such as the spark plug hole, eliminating disassembly, shortening inspection time, and reducing maintenance costs.

Precise Defect Identification: During the internal combustion engine manufacturing stage, the K-series endoscope can detect internal defects in components, such as engine block burrs and oil line cracks, to ensure factory quality. For example, an automobile manufacturer used this device to detect tiny cracks in turbine blades and promptly repair them to prevent failure.

Maintenance Process Monitoring: During maintenance, the endoscope provides real-time monitoring of repair progress, such as carbon deposit removal and component replacement, to ensure repair quality. In one case, technicians used an endoscope to guide specialized tools to remove carbon deposits from gas turbine blades, restoring their performance.

Matching Automotive Manufacturer Needs

Compliance with Industry Testing Standards: Automobile internal combustion engine inspections must comply with multiple standards, such as those for starting performance and speed regulation performance. The K-series endoscope's high-definition imaging and real-time transmission capabilities provide accurate data support for these tests, ensuring that inspection results meet industry standards.

Cost Control and Safety Improvement: By reducing disassembly and manual inspection time, the K-series endoscope helps automakers reduce inspection costs. Furthermore, its precise inspection capabilities can proactively detect potential faults, avoiding downtime or safety incidents caused by equipment failure, thereby improving production safety.

The VSNDT K-series industrial endoscope, with its technical advantages such as high-definition imaging, flexible inspection capabilities, and environmental resistance, effectively meets automakers' needs for efficient, accurate, and non-destructive testing in internal combustion engine inspections, including non-destructive testing, precise defect identification, and maintenance process monitoring. Its successful application in real-world cases, such as gas turbine inspection at a renowned heavy industry enterprise, further demonstrates its significant value in improving inspection efficiency and reducing maintenance costs.

Industrial borescope

solution service provider