Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

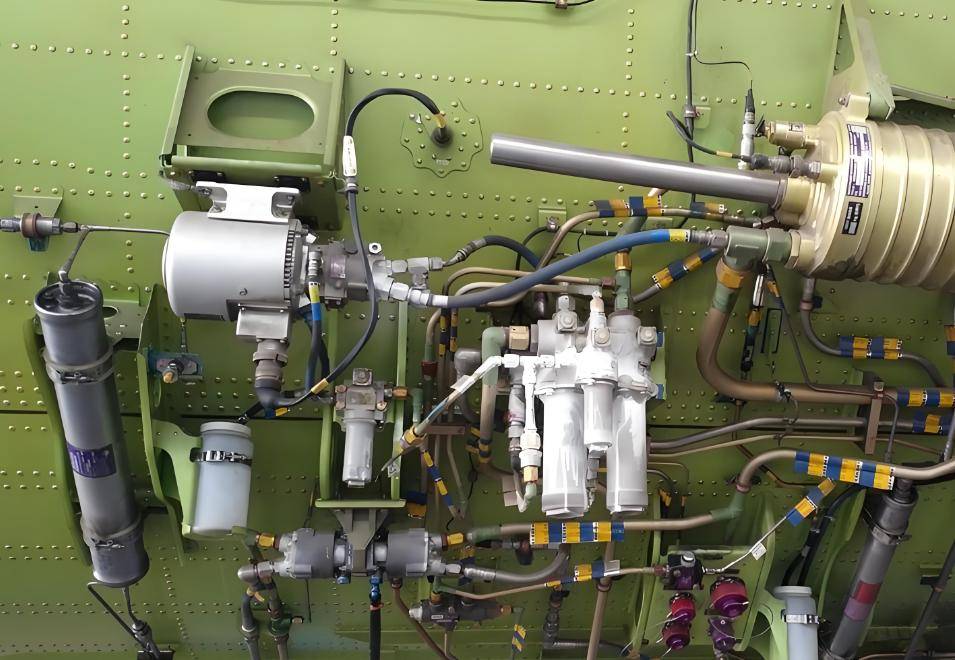

The application of industrial endoscopes in aircraft fuel tanks and pipelines is crucial. It can help technicians go deep into these areas that are difficult to observe directly and conduct detailed and accurate inspection,thereby ensuring the safety performance of the aircraft's fuel system and related pipelines. The following is a detailed description of the application of industrial endoscopes in aircraft fuel tanks and pipelines:

Inspection of interior corrosion and surface defect

Industrial endoscopes can go deep into the fuel tank and conduct a full range of corrosion and surface defect inspection on the tank wall. Through the high-definition camera and lighting system of the endoscope, technicians can clearly observe the condition inside the fuel tank, including corrosion spots, cracks, peeling and other defects, providing a basis for the maintenance and replacement of the fuel tank.

Inspection of residue and contaminant

During the long-term use of aircraft fuel tanks, some fuel residues, moisture or other contaminants may remain. These residues not only affect the quality of the fuel, but may also cause corrosion and damage to the fuel tank. The industrial endoscope can accurately detect the residues and contaminants inside the fuel tank, helping technicians to clean up in time to ensure the cleanliness of the fuel tank and the normal operation of the fuel system.

Inspection of welding and assembly quality

The welding and assembly quality of the fuel tank directly affects its sealing and safety. The industrial endoscope can carefully inspect the welds and assembly parts of the fuel tank to ensure that the welding quality is good and the assembly parts are tight and leak-free. This is of great significance for preventing fuel leaks and ensuring aircraft safety.

Inspection of internal blockage and foreign body

There may be blockages or foreign bodies inside the aircraft pipelines, which will affect the normal operation of the pipelines and the flow of fuel. The industrial endoscope can go deep into the pipeline to check whether there are blockages or foreign bodies, such as particles, sediments, etc. Once a blockage or foreign body is found, the technician can clean it in time to ensure that the pipeline is unobstructed.

Inspection of corrosion and wear

During use, aircraft pipelines may be corroded and worn by substances such as fuel, moisture, and oxygen. The industrial endoscope can inspect the corrosion and wear inside the pipeline, and observe the thickness changes of the pipe wall, corrosion spots, etc. These inspection data can provide important basis for the maintenance and replacement of pipelines.

Inspection of connection

The connection parts of aircraft pipelines are potential leakage points. The industrial endoscope can conduct detailed inspections of these parts to ensure that the connection is tight and leak-free. At the same time, the tightness and material status of the connection parts can be checked to detect potential fault hazards in time.

Industrial borescope

solution service provider