Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

In thedetection process, if the traditional detection tools are used, the clarity ofthe picture and the flexibility of the probe are lacking, which will cause thetransmitted picture to be unclear, and too small defects will be missed, and ifthe endoscope probe cannot articulate, the field of vision will not be wideenough, and hidden corners will not be visible;

With thedevelopment of industrial endoscope inspection technology, the pixel value ofthe camera has been greatly improved. Generally, the pixel value is above onemillion. Coupled with the blessing of the auxiliary lighting system, no matterhow small the internal flaws are can be clearly transmitted to the displayscreen;

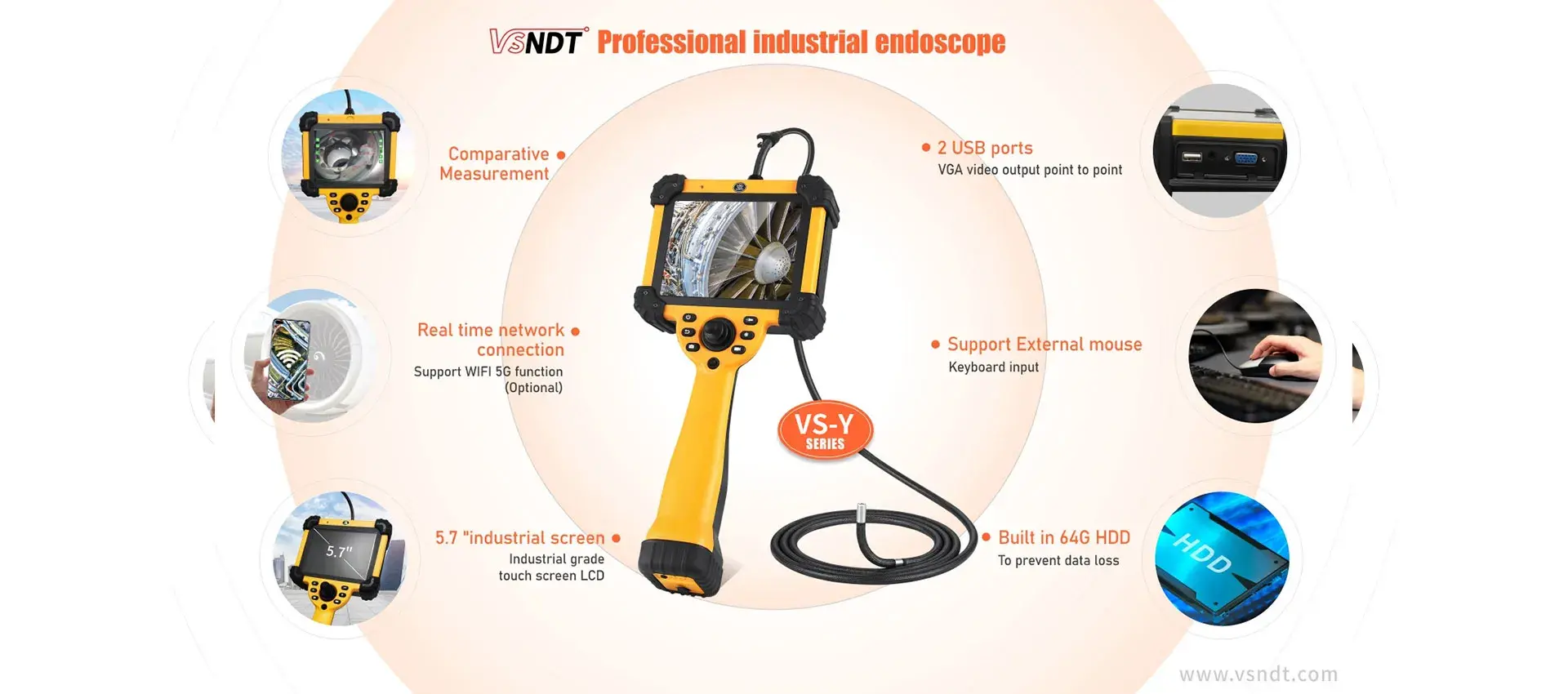

In addition tothe most basic ability to observe the picture, industrial endoscopes have alsomade new progress in the measurement of defects. During operation, only threedetection points need to be selected on the defect to establish a digitalreference plane. The system will automatically match the pixels on the image,even professional inspectors may not be able to achieve such accuracy;

The detectionand measurement technology using industrial endoscopes is very accurate for thedetection results and greatly reduces the error. Compared with the traditionaldetection methods before, the comparative measurement method can measure thedistance of defects more deeply and save inspectors more energy and time;

The traditionalobjective lens measurement is mainly a two-dimensional measurement method,which is affected by visual errors. Today's industrial endoscope comparativemeasurement method can be measured and verified in a three-dimensionaldimension, which avoids the error rate and further improves the accuracy ofdetection;

Industrial borescope

solution service provider