Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

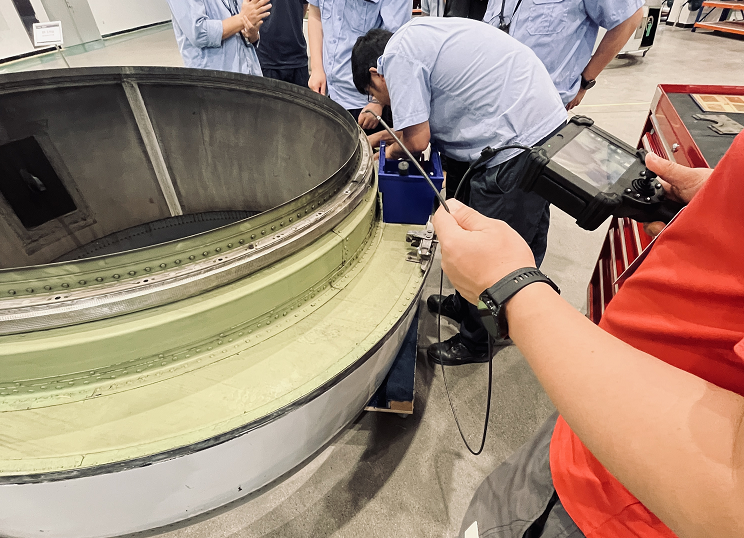

As a professional high-pixel industrial endoscope product, the P series industrial endoscope is particularly used in the aerospace field. In response to the needs of a well-known airline company to inspect the aircraft air intake cover, the P series industrial endoscope provides an efficient and accurate solution.

High-definition imaging and precise detection:

The P-series industrial endoscope has high-definition imaging capabilities, which can clearly show the details inside the aircraft air intake cover.

Through high-resolution image capture, inspectors can accurately identify potential problems such as wear, cracks, corrosion, etc. inside the air intake cover.

Flexible operation and in-depth detection:

The insertion tube of the endoscope is designed to be flexible and bendable, and can easily enter the complex structure inside the aircraft air intake cover.

The inspector can control the insertion tube of the endoscope through the operating handle to conduct all-round and multi-angle inspection inside the air intake cover.

Durability and Reliability:

The P series industrial endoscope is made of high-strength materials and has good wear and corrosion resistance. It can maintain stable operation in harsh aerospace environments and ensure the accuracy and reliability of detection results.

Improve detection accuracy:

The high-definition imaging capability of the P-Series industrial endoscope enables inspectors to more accurately determine the damage inside the aircraft air intake cover.

It avoids the misjudgment and missed detection that may occur in traditional detection methods and improves the detection accuracy.

Shorten detection time:

The flexible operability and in-depth detection capabilities of the endoscope enable inspectors to complete the inspection of the inside of the air intake cover more quickly, reducing the difficulty and time cost of inspection and improving inspection efficiency.

Reduce maintenance costs:

By timely discovering and addressing damage to the aircraft air intake cover, more serious damage and failures can be avoided. The number of repairs and repair costs are reduced, reducing the operating costs of airlines.

A well-known airline company used the P-series industrial endoscope to inspect the aircraft air intake cover. During the inspection, the endoscope successfully captured the tiny cracks and wear inside the air intake cover. The inspectors promptly repaired and replaced the cover based on this information, avoiding potential safety hazards. This successful case fully demonstrates the efficiency and accuracy of the Microvision P-series industrial endoscope in inspection tasks in the aerospace field.

In summary, the P series industrial endoscope, with its high-definition imaging, flexible operation, durability and reliability, has successfully helped a well-known airline company improve the inspection efficiency and quality of aircraft air intake covers. This solution not only meets the actual needs of the airline company, but also provides a strong guarantee for aviation safety.

Industrial borescope

solution service provider