Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

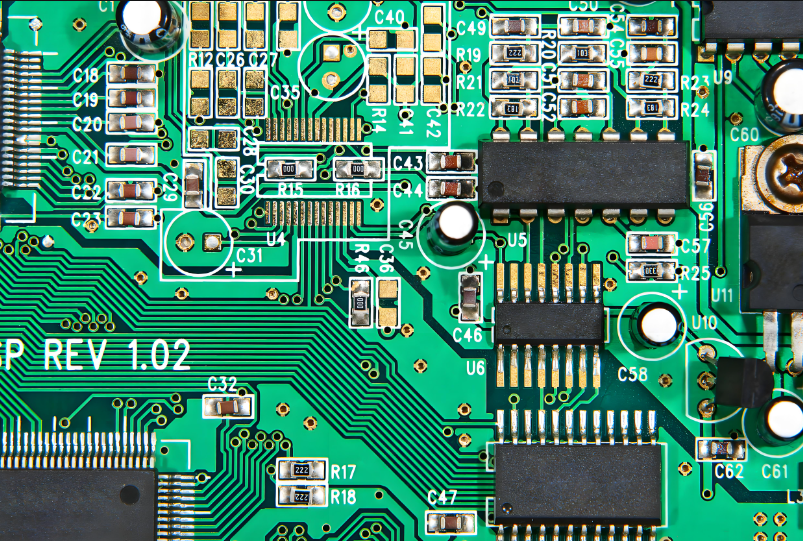

Industrial endoscopes play an important role in circuit board inspection. They can be used in welding quality inspection, internal structure inspection, defect location and evaluation, foreign body detection, repair and maintenance assistance, research and development and quality improvement, etc. They can effectively improve inspection efficiency and accuracy and reduce production costs.

Solder point inspection: Industrial endoscopes can inspect the quality of solder joints on circuit boards, including whether the solder joints are full, whether there are problems such as cold solder joints, cold solder joints, and bridging. Through high-definition imaging technology, the microstructure of the solder joints can be clearly observed to ensure that the welding quality meets the standards.

Component pin inspection: For surface mount components (SMD) and plug-in components, the endoscope can check whether the pins are correctly soldered and whether there is any offset, lift or short circuit.

Multi-layer PCB inspection: For multi-layer PCBs, the endoscope can check the connection between internal layers to ensure that the interlayer conduction is normal and there is no short circuit or open circuit.

Blind and buried via inspection: In the blind and buried via process, the endoscope can check whether there is residue in the hole, whether the hole wall is smooth, whether the copper layer is uniform, etc.

Crack detection: Industrial endoscopes can detect tiny cracks on circuit boards, especially in high-density interconnect (HDI) circuit boards, where cracks may cause interruptions in signal transmission or short circuits.

Delamination and blistering detection: During the circuit board manufacturing process, delamination or blistering may occur due to material problems or improper processes. Endoscopes can quickly locate these problems to avoid failures in subsequent use.

Residue detection: During the circuit board manufacturing process, solder slag, dust or other foreign matter may remain. The endoscope can check whether these residues affect the performance of the circuit board.

Contamination detection: For circuit boards that require high cleanliness (such as medical equipment or aerospace fields), the endoscope can detect whether there is contamination on the surface to ensure that the product meets the cleanliness requirements.

Fault location: When a circuit board fails, the endoscope can help technicians quickly locate the fault point, especially when the circuit board is encapsulated or difficult to observe directly.

Repair assistance: During the repair process, the endoscope can provide real-time images to help technicians operate accurately and avoid secondary damage to the circuit board.

Process optimization: Through endoscope inspection, R&D personnel can analyze defects in the circuit board manufacturing process, optimize process parameters, and improve product quality.

Failure analysis: In product failure analysis, the endoscope can provide detailed internal images to help analyze the cause of failure and propose improvement measures.

Non-destructive testing: No need to disassemble the circuit board, avoiding physical damage to the circuit board.

High-resolution imaging: Provides clear images for easy observation of tiny defects.

Flexibility: The bendable probe can enter small spaces and adapt to circuit boards of different shapes and structures.

Real-time detection: Able to observe the internal situation of the circuit board in real time, improving detection efficiency.

Consumer electronics: circuit board inspection for mobile phones, tablets and other devices.

Automotive electronics: quality control of vehicle circuit boards.

Aerospace: inspection of high-reliability circuit boards to ensure flight safety.

Medical equipment: cleanliness and defect inspection of precision medical circuit boards.

Industrial borescope

solution service provider