Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

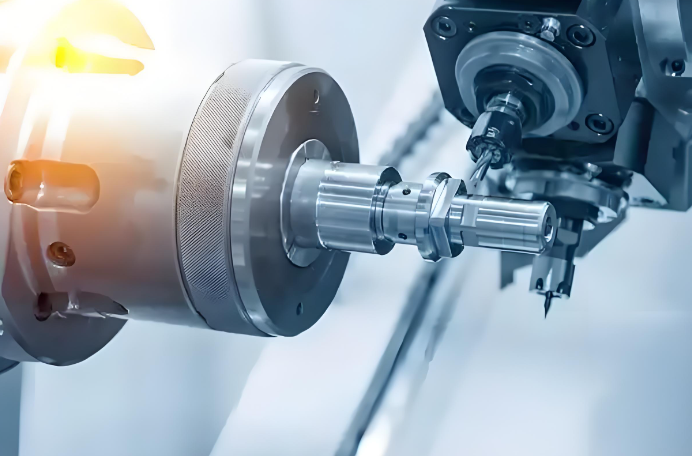

In the precision manufacturing industry, the stringent quality requirements and complex production processes demand high standards for inspection technologies. As a core non - destructive testing (NDT) technology, the Industrial Borescope plays a vital role in precision inspection, measurement, and evaluation by providing unique advantages that allow for in - depth examination of internal components and narrow spaces. This has made it an essential tool for ensuring product quality, improving production efficiency, and preventing potential risks. This article will explore the comprehensive value of Industrial Borescopes in precision manufacturing, focusing on core application scenarios.

The core goal of precision manufacturing is to achieve "zero - defect" production. Industrial Borescopes contribute to building a comprehensive quality control system by performing precise inspections of key processes and preventing defective products from being released from the source.

In sectors like aerospace, automotive parts, and high - end equipment manufacturing, the strength and sealing of welds directly determine product safety and service life. Traditional inspection methods often struggle to reach the hidden areas of welds, but Industrial Borescopes with flexible probes can deeply inspect areas such as weld roots and joints, clearly revealing defects like cracks, slag inclusion, lack of fusion, and porosity. High - end Industrial Borescopes even support real - time imaging and defect marking, and, when paired with image analysis systems, can quantify defect sizes, ensuring that welds meet international standards like ISO and AWS, fundamentally eliminating safety risks caused by weld defects.

The surface quality of precision components (such as turbine blades for engines, semiconductor chip packages, and medical device parts) directly affects their performance and lifespan. Even tiny scratches, micro - cracks, corrosion spots, or machining residues can lead to product failure. Industrial Borescopes, equipped with high - magnification optical lenses and high - definition imaging modules, can magnify surfaces dozens to hundreds of times, capturing micron - level defects and storing inspection data for quality traceability and process optimization. For components with complex structures such as curved surfaces and deep holes, the 360° rotating probe of the Industrial Borescope ensures comprehensive inspection without dead spots, greatly improving surface defect detection rates.

Precision assembly is a key stage in ensuring overall product performance. Misalignment, loose parts, missing fasteners, or improperly installed seals during assembly can cause operational failures. Industrial Borescopes can access assembly gaps and internal cavities that are difficult to inspect with the naked eye, allowing real - time visualization of assembly conditions, such as checking whether gear meshing gaps are uniform, if circuit board components are securely inserted, or if pipeline seals are properly placed. Through visual inspection, issues can be identified and corrected early in the assembly process, avoiding production delays and cost increases caused by rework, while ensuring consistency and reliability in product assembly.

Beyond qualitative inspection, the Industrial Borescope's precise measurement capabilities provide critical data for evaluating the performance of parts and the condition of equipment in precision manufacturing.

For precision components with special structures such as deep holes, blind holes, and irregular cavities, traditional measuring tools like calipers or micrometers cannot accurately reach or measure these dimensions. Industrial Borescopes, integrated with laser measurement and stereoscopic measurement capabilities, can precisely measure key dimensions such as hole diameter, wall thickness, gaps, and step heights without dismantling parts. Measurement accuracy can reach up to 0.01mm, fully meeting the design tolerance requirements of precision manufacturing. For example, in the processing of cooling holes in aerospace engine blades, a Borescope can simultaneously inspect the surface finish and diameter consistency of the holes, ensuring that the cooling performance meets design standards.

During the operation of precision equipment, the wear and corrosion of critical components directly affect equipment service life and operational safety. Industrial Borescopes can regularly inspect internal key parts of equipment (such as bearings, cylinder walls, and valve sealing surfaces) and, by comparing imaging data from different periods, analyze the wear and corrosion trends, scientifically assessing the remaining service life of components. This provides precise data for equipment maintenance. For example, in semiconductor manufacturing equipment, inspecting the corrosion status of vacuum chamber walls with a Borescope can help plan maintenance cycles in advance, preventing product scrap due to chamber leakage.

Downtime due to equipment failure in precision manufacturing leads to significant economic losses. Industrial Borescopes help reduce risks by enabling early detection of potential failures through preventive maintenance, significantly improving equipment operational stability.

By establishing a regular Industrial Borescope inspection schedule, the internal wear - prone parts and key stress areas of equipment can be continuously monitored, allowing for the early detection of cracks, loosened components, lubrication failure, and other potential fault signs. For instance, in high - end CNC machine spindle inspections, Industrial Borescopes can detect wear marks and lubrication conditions on spindle bearings, providing early warning of bearing failure, thus preventing equipment damage and production interruptions caused by spindle jams.

Dust, oil, metal shavings, and other contaminants inside precision equipment can affect accuracy and service life. Industrial Borescopes serve as a "visual assistant" for cleaning and maintenance tasks, guiding technicians to precisely locate areas where debris has accumulated, allowing targeted cleaning with specialized tools. For example, in electronic component packaging equipment, Borescopes can clearly show residual glue inside mold cavities, assisting technicians in thoroughly cleaning the area and preventing residual glue from affecting subsequent product packaging quality.

With its non - destructive, visual, and precise core advantages, the Industrial Borescope plays a crucial role throughout the entire production, maintenance, and R & D chain of precision manufacturing. It not only helps companies improve product yield rates and production efficiency but also effectively reduces equipment maintenance costs and failure risks, becoming an essential safeguard for high - quality development in precision manufacturing.

Shenzhen VSNDT is deeply involved in the development of internal visual inspection and Industrial Borescope products. With rich industry experience and technical expertise, we offer customized Industrial Borescope solutions tailored to the unique needs of industries such as aerospace, automotive, electronics, and medical devices. If you require assistance with selecting, customizing, or consulting on Industrial Borescopes and inspection technologies, feel free to contact us. Together, let’s build a strong quality defense line for precision manufacturing.

Industrial borescope

solution service provider