Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

Engine Manufacturing Department. The manufacturing details of the granules also have a significant impact on the overall performance of the engine, since the individual granules are fundamental components of the engine structure and overall system composition.

Service object:China's well-known automaker, Chinese brand auto leader

Industry:car

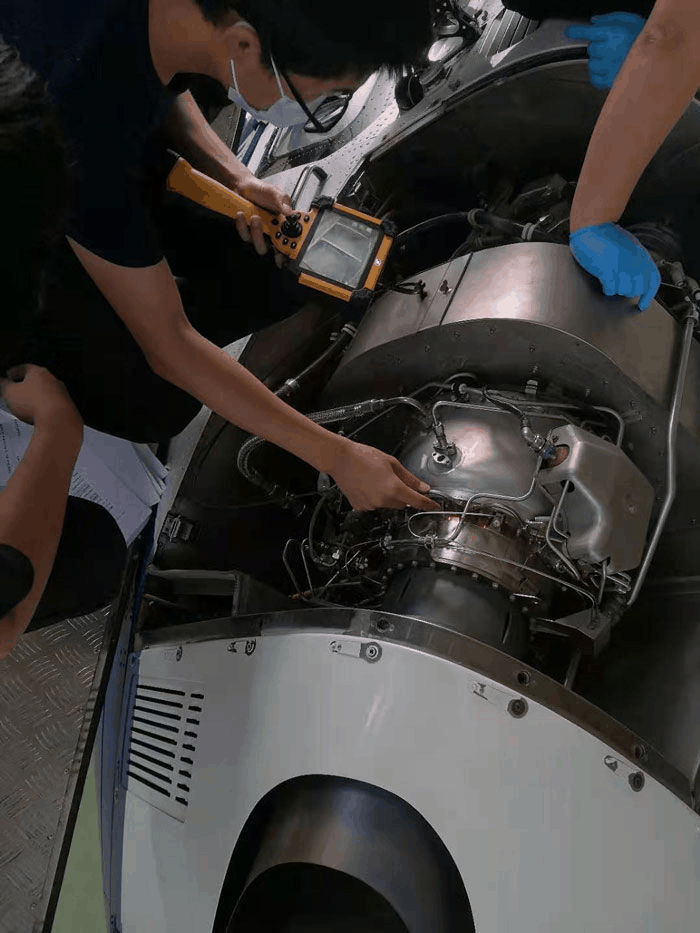

Using equipment: VS-F3910010 High Definition Megapixel Custom Series Industrial Videoscope

Detection conditions:The manufacturing quality of the automobile engine directly affects the performance of the automobile, so the detection object is very important for the automobile engine The manufacturing sector is extremely important and meaningful. The details of how the microsome is made also have a major impact on the performance of the engine, as the overall microsome is the engineThe basic components of the structure and the overall composition of each system. In order to maximize the performance of the engine, it is necessary to control the processing quality and processing progress of key components in the engine manufacturing process.

Solutions provided:In order to quickly check the inside of the motorcycle bracket bracket, we use WS-Y6010050 pixel high-definition series of industrial endoscopes. The diameter of the endoscope is6mm, the length is 5m. Equipped with a 360° omnidirectional head, it can realize 160° reverse visual inspection of slope shape. Due to the increased internal space of the locomotive track support, an endoscope with a length of 5 meters is used to detect the axial direction. AlthoughFor endoscopes with a general length of less than 3 meters, there may be some process requirements for the 5-meter-long borescope in the post-installation of the LED endoscope probe, but this length provides the ability to quickly detect and operate flexibly.

Main detection defect:The porosity, lack of material, texture, burr, transparent process in the process of processing Cleanliness etc.

Difficulties in detection:The detection space is small;There are many staggered holes and long detection time (average daily observation More than 18 hours), the endoscopic probe is easily damaged with the surface of the casting for a long time.

Solutions provided:In order to observe and detect small defects, we use WS-F3910010 HD mega Pixel custom series industrial videoscope. Optical fiberLight guide and rear high-power LED, sufficient and guaranteed light intensity; When the inspection is closed, the collision between the lens and the object under observation will not affect the consumption of light source, and also increase the endoscopic Mirror consumption; and it is convenient to replace the pipe, which can reduce the after-sales cost.

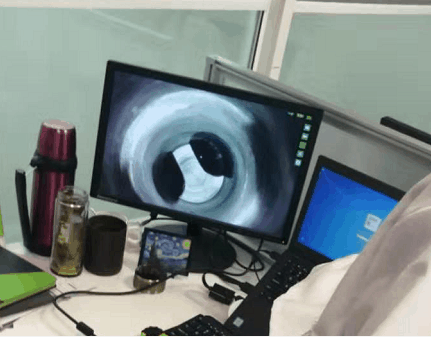

Summary Summary: VS-F3910010 high-definition megapixel custom series industrial videoscope can not only reflect sound The interior of the engine block can also quickly detect small defects on the inner surface. On the premise of satisfying the visual inspection, the equipment takes more into account the internal defects of the engine and the maintenance cost of user upgrades. Professional is to think and solve problems on behalf of customers. Very satisfied with a cooperation.

Service scenario:

Detection map:

Industrial borescope

solution service provider