Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

The automotive maintenance industry also uses industrial endoscopes more frequently. For example, what are the problems with cars that cannot be seen with the naked eye? At this point, it is necessary to use industrial endoscopes for automotive maintenance. How much is the cost of industrial endoscopes for automotive maintenance?

The prices of car repair endoscopes range from 200 to 6000, mainly depending on which one is more suitable for manufacturers to use, mainly depending on factors such as lens diameter, pixels, depth of field, lens selection, and operational control.

There are many uses for endoscopes used in automotive maintenance. The automotive repair endoscope is a type of automotive repair endoscope developed and designed for the field of automotive manufacturing and maintenance.

Mainly used for detecting and diagnosing situations such as car engines and carbon blockage, the introduction of automotive repair endoscopes greatly reduces repair time and costs, while also avoiding damage caused by multiple disassembly and assembly of components.

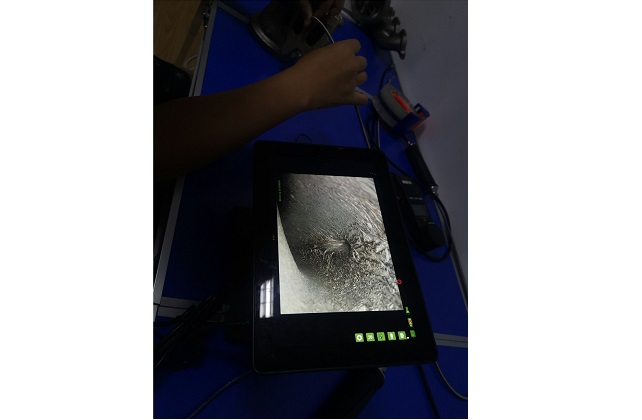

Before cleaning the engine, observe the carbon buildup inside the engine using an endoscope and take photos. Not only does it avoid unnecessary disassembly, but it can also accurately and efficiently locate car lesions.

After cleaning, observe and take photos again. Then compare the images observed before and after cleaning, and the entire maintenance process is very clear and environmentally friendly, meeting the concept of green auto repair.

The endoscope can not only observe the internal condition of the engine for inspection. Moreover, it is possible to observe whether there are cracks in the engine block, the internal condition of the gearbox, the water tank, and other areas that can be touched but cannot be seen. Intuitively, it can be seen that car problems are mainly applied in the automotive repair industry. It is easy to detect and observe the narrow and difficult to see parts of the pipeline. In automotive maintenance, endoscopes are mainly used to detect and diagnose the wear, carbon accumulation, and blockage of automotive engines, cylinders, fuel pipes, engines, mufflers, conveying systems, differentials, water tanks, fuel tanks, and gearboxes, improving work efficiency and reducing repair costs, At the same time, it avoids damage caused by multiple disassembly and assembly of the machine components.

In the cleaning and maintenance of car engines, car endoscopes are a very good helper. Especially in the diagnosis of valve carbon accumulation, it plays a crucial role. Generally speaking, there are two diagnostic methods available in professional repair shops.

Carbon deposition detection method

1. The disassembly method is to disassemble the engine and check for any carbon buildup. This is very intuitive, but it is time-consuming and labor-intensive, and every time any component is disassembled, it will more or less affect its performance and shorten its service life.

2. Endoscopic inspection: Remove the spark plug or fuel injector and use an endoscope to observe the degree of carbon buildup on the valve.

Its main feature is that the formation and combustion process of the mixture in the combustion chamber, as well as the working state of the cylinder, valve, and piston crown at high temperatures, can be observed under the working state of the engine. The above images are recorded with the crankshaft angle as an indicator through a high-speed camera. At the same time, it can also be connected to a computer, and with the help of corresponding image processing software, specific image frames can be called up, slowed down, locally enlarged, and interpreted at any time.

This visualization technology is not only a powerful assistant for automotive design and development, but also a tool for automotive technology training and teaching. It can be seen that automotive endoscopes have been widely recognized by users in the automotive repair industry, and its simple and flexible operation is an essential detection and diagnosis tool in the automotive repair industry.

Introduction to the Multiple Uses and Functions of Automobile Repair Endoscopes. It is generally known that automobile repair endoscopes can detect carbon deposits in engine cylinders. In fact, automobile repair endoscopes can also be used to inspect areas such as engine cylinder block, valves, piston crown, three-way catalytic converter, evaporation box, automobile fuel injectors, pipelines, and vehicle body gaps. Through visual detection, the operating status of the car can be truly reflected, as well as other troubleshooting.

Today, I have shared with you the content about industrial endoscopes for automotive maintenance. The above content is provided by Shenzhen Micro Vision Optoelectronics. If you have any questions, you can call to inquire.

Industrial borescope

solution service provider