Want to know more?

Don't miss any product updates on our industrial borescopes

Industrial borescope

solution service provider

Company Address

Office : 18F, Pingshanshouzuo, Pingshan District, Shenzhen,Guangdong

Contact Info

Ph: +86-0755-89588241

As a measuring element, sensitive element, and compensation element in the mechanical industry such as automatic control and measuring instruments, it can transport various working media. This product can be applied from vacuum to high pressure, Various application conditions from low to high temperatures. The products are widely used in industries such as aerospace, scientific research, instrumentation, metallurgy, chemical industry, construction, textile, pneumatic, etc.

Customer Overview:

The client is a certain unit that mainly develops and produces corrugated tube elastic components. Due to the high product density and strict process quality, there may be some small defects during the research and production process, such as scratches, pinholes, etc., which cannot be recognized by the naked eye. The client hopes to find a cost-effective domestic endoscope to control production quality through equipment testing.

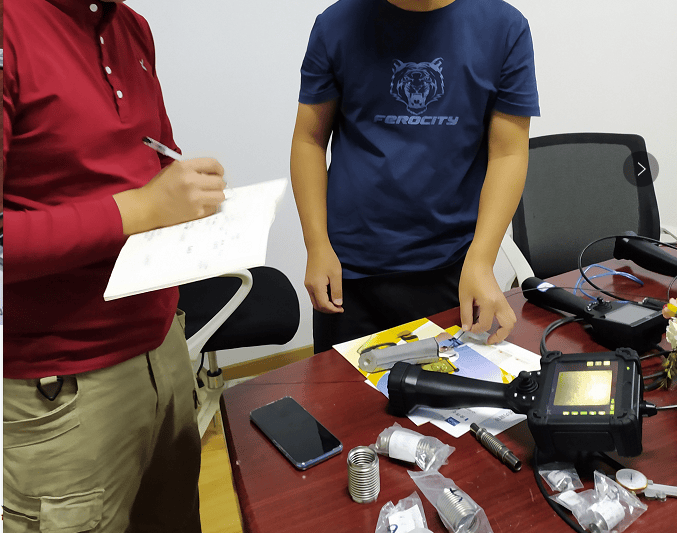

The customer can check and inquire about the use of industrial endoscopes through the company's official website. After understanding the customer's needs, our company can cooperate with the customer to conduct visual inspection analysis. After the customer communicated with our technical director in various technical aspects to reach a solution, X Research Institute engineers visited our company with the product, hoping to solve the testing problem for this purpose.

Site Overview:

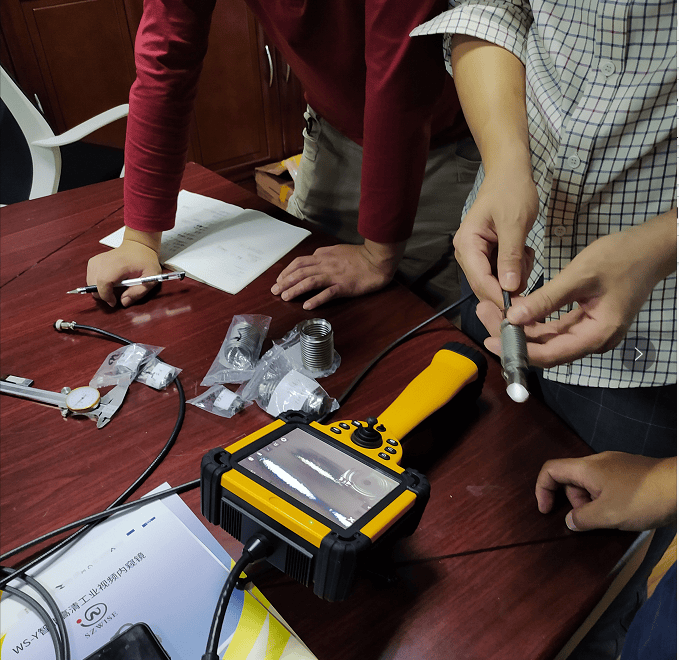

The client's representatives mainly include the technical department, engineering department, and responsible person. After our company communicated and listened to our technical personnel explain the product again, the relevant responsible personnel of the customer actually operated the WS-Y series industrial endoscope of Shenzhen Micro Vision Optoelectronic Technology Co., Ltd., and affirmed the equipment's clarity and other functions.

Solution:

1. 1 million high-definition pixels, which can meet the internal observation requirements of transportation and rail transit extrusion plate grooves, welding scar defects, internal debris and other defects in the extrusion groove. The reflection of the extrusion groove wall is perfectly solved, and it can intuitively and clearly determine whether the observation part is qualified. The photos, videos, and archived images are clear.

2. It can intelligently edit images and mark defects. And customize image watermarks for easy post-processing and traceability.

3. Built in 64G solid-state drive to prevent data loss, with 2 USB ports and VGA video output point to point.

Through extensive testing and communication, we ultimately resolved the difficulties for our clients and reached a cooperation agreement. We also appreciate the trust and support they have placed in our company. It is our mission to address their needs.

Industrial borescope

solution service provider